With growing concerns about environmental impact and toxicity, halogen-free flame retardants (HFFRs) have emerged as critical alternatives to traditional brominated/chlorinated systems.

Why Choose Halogen-Free?

Halogen-free flame retardants avoid bromine/chlorine while providing:

- Reduced toxic fume emission during fires

- Better recyclability of treated materials

- Compliance with strict regulations (e.g., EU RoHS, REACH)

- Lower bioaccumulation risks

Key Halogen-Free Flame Retardant Materials

1. Phosphorus-Based Compounds

- Types:

- Organic: Resorcinol bis(diphenyl phosphate) (RDP)

- Inorganic: Red phosphorus, ammonium polyphosphate (APP)

- Mechanism: Forms insulating char layer through dehydration reactions

- Applications: Epoxy resins, polyurethane foams

2. Nitrogen-Based Systems

- Examples: Melamine cyanurate, guanidine sulfamate

- Action: Releases inert gases (NH₃, N₂) to dilute flammable vapors

- Efficiency: Often combined with phosphorus for synergy

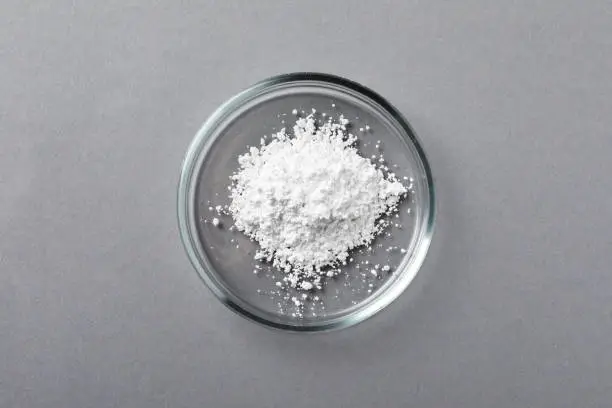

3. Mineral Fillers

| Material | Activation Temp. | Key Feature |

|---|---|---|

| Aluminum Hydroxide | 200-300°C | Smoke suppression |

| Magnesium Hydroxide | 300-340°C | Higher thermal stability |

| Huntite/Hydromagnesite | 220-550°C | Self-charing properties |

Usage: 50-65% loading in cables, rubber products

4. Silicon-Based Additives

- Forms: Silicones, silica nanoparticles, silsesquioxanes

- Advantage: Enhances thermal stability without heavy metal content

Performance Comparison: Halogen vs. Halogen-Free

| Parameter | Halogen-Based | Halogen-Free |

|---|---|---|

| Toxicity | High (dioxins) | Low |

| Smoke Density | High | Moderate |

| Processing Temp | <200°C | 200-350°C |

| LOI* Improvement | 22-28 | 24-32 |

*Limiting Oxygen Index

External References:

Leave A Comment

You must be logged in to post a comment.