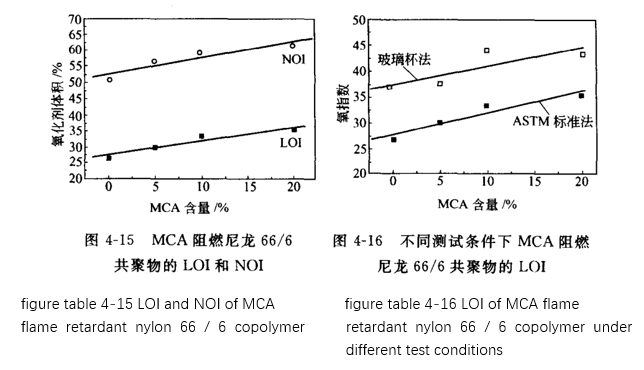

It can be seen from the figure table 4-15, both the NO and LOI values increase with the increase of the amount of melamine cyanurate, meanwhile the slope ratio of the two regression lines is OI / NOI = 0.82, indicating that the fire retardant effect of MCA on nylon may occur in the condensed phase. This is different from the sublimation endothermic physical fire retardant action method previously recognized by most researchers. G. Camino further uses the glass method of the LOI of melamine cyanurate fire retardant nylon (that is, fire retardant nylon is placed in a glass cup. When testing the LOI, keep the melt in the burning atmosphere of the flame and not lose it) test, and compare with the standard LOI test method of ASTM D2863, the results are shown in Figure 4-16. It can be seen from the figure that the LOI value of the cup method is higher than the standard LOI, and the trend of increasing with the increase of the amount of MCA is similar. The slope ratio of the two straight lines is 1.1. These results indicate that MCA still has a good fire retardant effect on nylon even in the absence of droplets. Therefore, the fire retardant effect of melamine cyanurate on nylon is not only the physical process of endothermic absorption of droplets or sublimation, but a more important fire retardant mechanism.

Leave A Comment

You must be logged in to post a comment.